CHA Industries SE 400 RAP, Thermal Resistance

Belljar Evaporator.

Equipment Details:

Vacuum evaporator

Motorized hoist

Diffusion pump, 6″

WELCH 1376 Pump

Molecular sieve trap with timer,

30″x18 ” Glass belljar with guard,

Feedthru collar 18″ DIA,

6kW SCR Power, Heater with

Temperature controller

Power: 208VAC/3 Phase/60Hz, 5Wires, 80 Amps.

OPTIONS, SUPPORT EQUIPMENT, DELIVERY, SETUP, START-UP & SPARES AVAILABLE

BUYER IS RESPONSIBLE FOR ANY FREIGHT OR CRATING COSTS.

===========================================================================================================================================

CVC Products Inc., CV 18 Resistance

Thermal Evaporation Bell-jar System,

Includes Automatic Valve Control of pump down cycle AVC 485

3.6 KVA SCR filament control

Heavy Duty tap switches

18” x 18” Pyrex Bell-Jar

substrate stage rotation electric drive motor

GIC 410 Ion Gauge Control

Refurbished Neslab HX 75 Air to Water Chiller

CVC PBA 100 Package expanded Diffusion Pump (PMVS 100 6” Expanded pump)

w/ Multi-coolant trap ( BC- 61D) PBA 100 2500 l/sec 1800 Watt

CVC Multi Coolant Baffle and a CVC Goldline 6” Diffusion Pump

1998 vintage,

Inspections Welcome,

Refurbished with 30 Day Warranty.

Filament Control – Heavy Duty Tap Switch

Base Price: $4,500.00

BUYER IS RESPONSIBLE FOR ANY FREIGHT OR CRATING COSTS.

========================================================================================================================================================================================================================================================================================================================

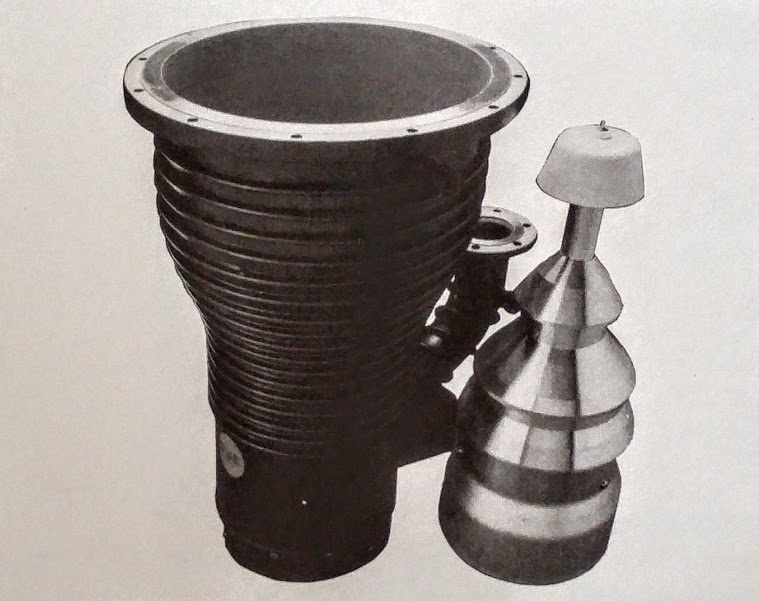

Davis and Wilder 2400 Thermal Evaporation SST Bell-jar System

System Description: Davis & Wilder Inc., Sunnyvale CA. (D&W) Resistance (thermal) Evaporation System. This will be a fully operational system, with the following features and support equipment. System is exact system represented in images.

Davis & Wilder Inc., 2400 Evaporator

Frame- 48” W X 34” D footprint 25”

O ring seal, stainless steel bell jar, shielding with two view-ports. CTI 8 Cryopump, Temp Monitor and Compressor.

Pneumatic SST gate valve. SST pneumatic roughing, regen and associated manifolding.

5KVA SCR control panel with manual/ Maxtek switch and digital current readout. HD 600V 3 boat tap switch.

HSD valve sequencer/auto cryo regeneration with Granville Phillips 340 Ion/convectron Gauge.

Maxtek MDC 360 film thickness controller with remote control with Maxtek dual crystal head.

Sites for three typical configuration thermal evaporation boats with source shutter.

Single static substrate stage, up to 24” from sources. Stage has tilt and offset adjustments.

Quartz Halogen substrate heater with digital temperature controller.

OPTIONS, SUPPORT EQUIPMENT, DELIVERY, SETUP, START-UP & SPARES AVAILABLE